Choose whether you are working with existing hardware or designing new hardware. To minimize breakaway friction an O-Ring groove must be wide enough to allow rolling or twisting of the seal. Apple rubber o ring groove design.

Apple Rubber O Ring Groove Design, Groove Bore Piston Rod Figure 1-2. Designing the parts of an application where o-rings will be applied is broadly termed o-ring groove design. Browse design considerations and recommendations for static face seals metric o-rings static dovetail o-rings static rod-piston o-rings and dynamic rod-piston o-rings. The new Inspection Specifications addition to the Seal Design Guide includes information on.

Groove Design O Ring Seals Minnesota Rubber Plastics From mnrubber.com

Groove Design O Ring Seals Minnesota Rubber Plastics From mnrubber.com

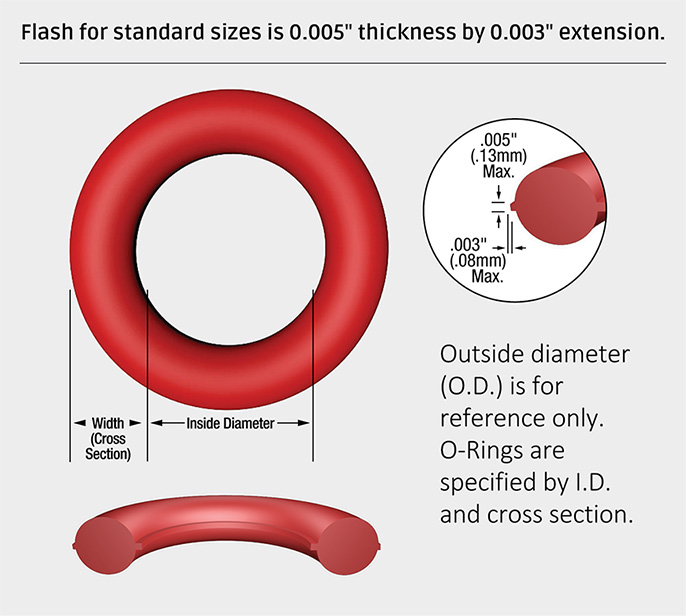

Male or Plug - the O-ring groove is located on a plug which is inserted into the housing or cylinder fig. Standard-sized O-rings are readily available in the following materials. Grooves for PTFE O-Rings are similar to those for rubber O-Rings except that less squeeze is applied due to the relative stiffness of the material. Having a circular cross section that functions as a seal in both static and dynamic applications by being compressed between the mating surfaces comprising the walls of the gland in which it is installed.

Black Nitrile Buna-N 70 or 90 Brown or Black Viton 75 Black EPDM 70 Red Silicone 70 Black Neoprene 70 and White PTFE.

Read another article:

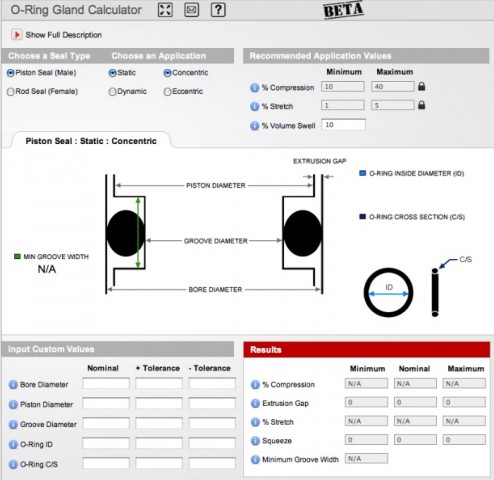

Standard-sized O-rings are readily available in the following materials. If you are unsure what cross-section size to use see here. O-ring groove design guides offer default dimensional guidance on the most basic o-ring groove design applications. Cross-section Select a Quad-Ring Brand cross-section size from the available standard sizes. For those who are unfamiliar with O-ring design it is rec-ommended to fi rst.

Source: skf.com

Source: skf.com

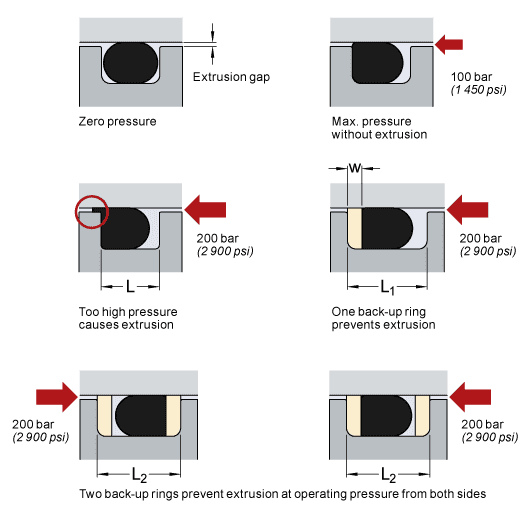

The second number that is required is the O-ring Series that you. On the flip side an External Groove aka a male gland the design will be based on the minimum bore diameter that the o-ring will seal against. Expert Application Engineering Assistance. Review the general o-ring groove design. O Rings And Back Up Rings Skf Skf.

Source: applerubber.com

Source: applerubber.com

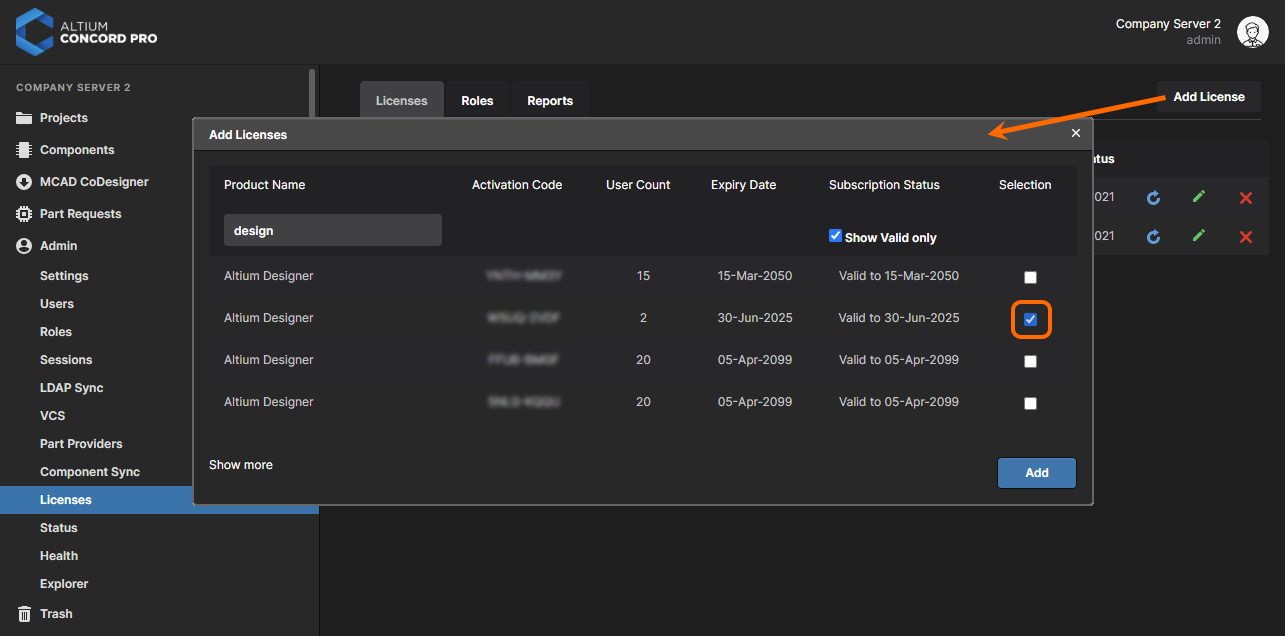

- Before installation and where applicable make sure to lightly coat the O-ring with a compatible lubricant. Depending on your application you can have the groove be cut in either the piston or the bore. The second number that is required is the O-ring Series that you. Expert Application Engineering Assistance. New Gland Calculator Tool At Applerubber Com Official Apple Rubber Blog.

Source: globaloring.com

Source: globaloring.com

These type of glands are used for a variety of applications bolted flanges or removable lids. - Before installation and where applicable make sure to lightly coat the O-ring with a compatible lubricant. Depending on your application you can have the groove be cut in either the piston or the bore. You will find in-depth information on each of these rules and more in the new Seal Design Guide published by Apple Rubber Products. Bs 4518 Metric O Rings Global O Ring And Seal.

Source: in.pinterest.com

Source: in.pinterest.com

Apple Rubber Products Inc a leading provider of O-rings and sealing solutions now features an updated Seal Design Guide complete with newly added Inspection Specifications. For those who are unfamiliar with O-ring design it is rec-ommended to fi rst. Groove Bore Piston Rod Figure 1-2. Female or Tube - the O-ring groove is located in the housing or cylinder and a tube is installed through the O-ring. Pin On Smartwatch Bands.

Source: mnrubber.com

Source: mnrubber.com

On the flip side an External Groove aka a male gland the design will be based on the minimum bore diameter that the o-ring will seal against. Try our new Online O-ring Store. The second number that is required is the O-ring Series that you. The best o-rings are useless without the right groove design which becomes increasingly important the more demanding the application environment. Groove Design O Ring Seals Minnesota Rubber Plastics.

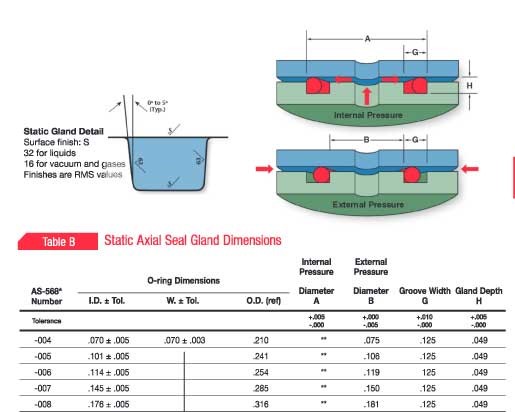

This is the first number that is needed. In reciprocating sealing applications there is a back and forth or reciprocating motion along the shaft axis between the inner and outer parts of the gland. Depending on your application you can have the groove be cut in either the piston or the bore. Now follow the steps below to design your own o-ring seal and o-ring groove. Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials.

Source: es.pinterest.com

Source: es.pinterest.com

Standard and Metric Sizes. On the flip side an External Groove aka a male gland the design will be based on the minimum bore diameter that the o-ring will seal against. To minimize breakaway friction an O-Ring groove must be wide enough to allow rolling or twisting of the seal. Female or Tube - the O-ring groove is located in the housing or cylinder and a tube is installed through the O-ring. Montre F1 Carbon Gmt Concept Watch Cool Watches Watch Design Watches For Men.

Source: applerubber.com

Source: applerubber.com

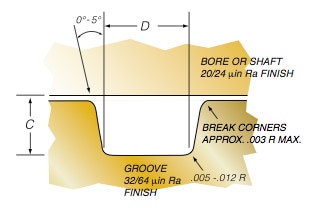

Designing the parts of an application where o-rings will be applied is broadly termed o-ring groove design. Use a good O-ring grease like Molykote 55 or 111. On the flip side an External Groove aka a male gland the design will be based on the minimum bore diameter that the o-ring will seal against. Based on the cross section CS of your O-ring you will choose the corresponding O-ring groove depth and O-ring groove width dimensions. The Apple Rubber Seal Design Guide Turns 25 Official Apple Rubber Blog.

Source: vizeng.com

Source: vizeng.com

If you are unsure what cross-section size to use see here. PTFE rings may work for you but could be marginal. Also the groove width is generally less as PTFE O-rings are much less likely to roll in reciprocating applications than their elastomeric counterparts. The O-ring Figures 1-2 and 1-3. How To Design An O Ring Groove Vizeng.

Source: pinterest.com

Source: pinterest.com

Having a circular cross section that functions as a seal in both static and dynamic applications by being compressed between the mating surfaces comprising the walls of the gland in which it is installed. To minimize breakaway friction an O-Ring groove must be wide enough to allow rolling or twisting of the seal. Cross-section Select a Quad-Ring Brand cross-section size from the available standard sizes. The O-ring inner diameter ID should also stretch approximately 5 over your groove or gland. 1pcs 6016 2rs 6016 Rs 80x125x22mm Rubber Sealed Deep Groove Ball Bearing Brand New Deep Rings For Men Groove.

Source: vizeng.com

Source: vizeng.com

Standard-sized O-rings are readily available in the following materials. To minimize breakaway friction an O-Ring groove must be wide enough to allow rolling or twisting of the seal. The design of the groove where the o-ring sits plays a major role in how the o-ring performs its sealing role. The second tradeoff is that 90 durometer rings are less tolerant of a poor finish so you need to maintain the prescribed 16 rms finish on the bore and groove OD. How To Design An O Ring Groove Vizeng.

Source: studylib.net

Source: studylib.net

Quad-Ring Brand Seals for Static and Non-Rotary Dynamic Applications. One of the faces will be completely smooth and one will have an o-ring groove cut into it. O-ring and gland constitute the classic O-ring seal assembly. In the long stroke of a reciprocating seal application this twisting action can strain and eventually tear the rubber causing a failure mode known as spiral twist. O Ring Basics Apple Rubber.

Source: pinterest.com

Source: pinterest.com

PTFE rings may work for you but could be marginal. Browse design considerations and recommendations for static face seals metric o-rings static dovetail o-rings static rod-piston o-rings and dynamic rod-piston o-rings. The O-ring inner diameter ID should also stretch approximately 5 over your groove or gland. Basic Application Groove Design Reference Charts - Expert Application Engineer Support. Protect Your Ipad 9 7 Model By Utilizing This Protective Rugged Case With Rubber Bumpers Comes With Handstrap Br Water Proof Case Ipad Case Ipad Accessories.

Source: pinterest.com

Source: pinterest.com

Oring Groove Design As important as the oring seal itself is the groove that the oring seats into. Standard-sized O-rings are readily available in the following materials. Make sure that the material you choose will withstand the temperature of your system by. An O-ring is a circular cross-section ring molded from rubber. Tap Reseater Washer Assortment 125 Pc Washer Flat Washer Dryers For Sale.

Source: applerubber.com

Source: applerubber.com

Preliminary O-ring Design Considerations. If the O-ring size required is known simply select the AS BS or ISO standard such as. You will find in-depth information on each of these rules and more in the new Seal Design Guide published by Apple Rubber Products. Try our new Online O-ring Store. O Rings Standard As568 Iso 3601 Apple Rubber Products.