Higher design pressures for non-ammonia applications. Pressure a conceptual cycle analysis and preliminary design of a refrigeration system. Ammonia thermosyphon design.

Ammonia Thermosyphon Design, F 950 Leaving pressure psig 1818 Circulation rate 2 Surge drum height adder ft 17 Fluid type Bitzer compressor oil Fluid mass flow rate lbmin 2511 Entering fluid temp. 2 Baffle spacing and cut. 20MPa Water pressure test. Thermosyphon cooling can be used as an auxiliary cooling system in household refrigerators and airplanes He et al 2017.

Thermosyphons An Overview Sciencedirect Topics From sciencedirect.com

Thermosyphons An Overview Sciencedirect Topics From sciencedirect.com

Ammonia is 100 natural does not harm the environment and is the most efficient refrigerant available. F 1800 Leaving fluid temp. 3 Inlet piping length diameter and details of fittings. 1 Tube length inside and outside diameter and pitch.

Thermosyphon cooling can be used as an auxiliary cooling system in household refrigerators and airplanes He et al 2017.

Read another article:

Designers of thermosyphon systems strive for a circulation ratio of 31 for ammonia and 21 for R-22 where the circulation ratio means the rate supplied to the heat exchanger divided by the rate evaporated. The recommended pressure gradients11 for this pipe are 226 Pam 01 psi per 100 ft for ammonia and 113 Pam 05 psi per 100 ft for R-22. Ammonia is 100 natural does not harm the environment and is the most efficient refrigerant available. Thermosyphon cooling can be used as an auxiliary cooling system in household refrigerators and airplanes He et al 2017. Industrial refrigeration systems primarily use ammonia as a refrigerant.

Source: youtube.com

Source: youtube.com

20MPa Water pressure test. The fouling resistance for condensing steam can be taken as 000005 -. Mass flow lbmin 820 Target evaporator temp. As a result the fouling resistance may be a major part of the total resistance and is thus a critical factor in the design. Ammonia Refrigeration Ammonia Evaporator Animation Youtube.

3 Inlet piping length diameter and details of fittings. Our deep knowledge of the principles of refrigeration systems allows us to create custom. Consider that the normal inlet oil temperature is 175 to 180 degrees F 607- to 644-psi saturated ammonia NH3 pressure and outlet oil temperature is 120 to 140 degrees 300- to 394-psi saturated NH3 pressure. When designing a thermosyphon oil cooling system one usually begins with the design oil cooler heat rejection and an assumed refrigerant overfeed rate say 41. 2.

Source: freeenergyplanet.biz

Source: freeenergyplanet.biz

One soon-to-be-released thermosiphon-based cooling system for consumer computing is IceGiants ProSiphon Elite CPU Cooler. Oliveira et al 2016. Thermosyphon piping loop is exactly equal to the pressure differential supplied by the difference in fluid densities and the height of the vertical legs in the piping loop. The fouling resistance for condensing steam can be taken as 000005 -. How Do Thermosyphon Systems Work Solar Water Heater.

Source: sciencedirect.com

Source: sciencedirect.com

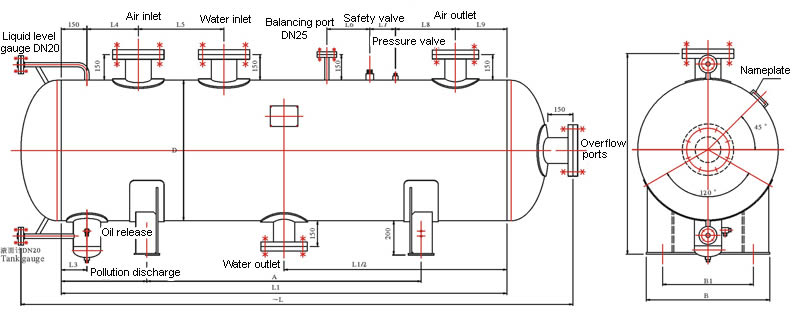

Thermosyphon piping loop is exactly equal to the pressure differential supplied by the difference in fluid densities and the height of the vertical legs in the piping loop. The recommended pressure gradients11 for this pipe are 226 Pam 01 psi per 100 ft for ammonia and 113 Pam 05 psi per 100 ft for R-22. Thermosyphon Receivers are secondary vessels placed between the high pressure receiver and the expansion device to store both system liquid and liquid that is used to cool the compressor lubricant. Consider that the normal inlet oil temperature is 175 to 180 degrees F 607- to 644-psi saturated ammonia NH3 pressure and outlet oil temperature is 120 to 140 degrees 300- to 394-psi saturated NH3 pressure. Ammonia Water An Overview Sciencedirect Topics.

Source: ref-wiki.com

Source: ref-wiki.com

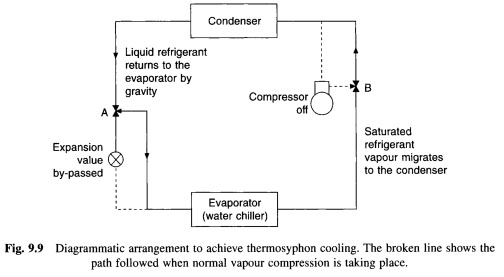

Thermosyphon cooling can be used as an auxiliary cooling system in household refrigerators and airplanes He et al 2017. Features When a refrigerating compressor unit is used in the refrigeration system a thermosiphon liquid receiver is required to separate the refrigerating medium from return-gas in oil condenser. As ambient temperatures fall below the return water temperature free cooling is available by thermosyphon circulation of refrigerant around the chiller without running compressors. Ammonia R-717 Systems Refrigeration Design Installation Industrial Ammonia R-717 Refrigeration Installation. Thermosyphon Cooling.

Source: creativesafetysupply.com

Source: creativesafetysupply.com

Freechiller annualised Coefficient of Performance COSPs ranges between 10 to 15 depending on design temperature chiller configuration and method of heat rejection. Thermosyphon oil coolers for compressors have been designed in several ways. Ammonia R-717 Systems Refrigeration Design Installation Industrial Ammonia R-717 Refrigeration Installation. Refrigeration systems professionals at Discovery Designs Refrigeration LLC have the expertise to design and install thermosiphon systems in ammonia or CO2 refrigeration systems. Ammonia Pipe Marking Label Thermosyphon Return.

Source: ddref.com

Source: ddref.com

Geometric information is required by the program. 3 Inlet piping length diameter and details of fittings. Thermosyphon oil coolers for compressors have been designed in several ways. This training video describes in more detail the process scheme of an ammonia refrigeration unit with a system of measuring instruments for process. Industrial Refrigeration Systems Screw Compressors Piping Design Ammonia And Co2 Refrigerant And Cold Storage Construction Services For Businesses Throughout The United States Discovery Designs Refrigeration Llc Mukwonago Wisconsin 53149.

Source: simmakers.com

Source: simmakers.com

F 1800 Leaving fluid temp. The thermosiphon is like a flooded system flow rate is typically 31 up to 101 or more but generally I stick to 51. The fouling resistance for condensing steam can be taken as 000005 -. The recommended pressure gradients11 for this pipe are 226 Pam 01 psi per 100 ft for ammonia and 113 Pam 05 psi per 100 ft for R-22. Thermosyphon Technology For Ground Freezing Simmakers Ltd Company.

These oil coolers are typically ASME pressure vessels and bear an ASME stamp. Thermosyphon oil coolers for compressors have been designed in several ways. Consider that the normal inlet oil temperature is 175 to 180 degrees F 607- to 644-psi saturated ammonia NH3 pressure and outlet oil temperature is 120 to 140 degrees 300- to 394-psi saturated NH3 pressure. 1 Tube length inside and outside diameter and pitch. 2.

Source: sciencedirect.com

Source: sciencedirect.com

Features When a refrigerating compressor unit is used in the refrigeration system a thermosiphon liquid receiver is required to separate the refrigerating medium from return-gas in oil condenser. 1 Tube length inside and outside diameter and pitch. I generally design my thermosiphon lines with the typical 2 PSI loss per 100ft liquid and 1 PSI loss per 100ft suction plus one size larger for wet suction. The properly designed thermosyphon receiver will guarantee the preferential flow of liquid refrigerant to the oil cooler before satisfying other system requirements for liquid. Thermosiphon System An Overview Sciencedirect Topics.

Source: chineserefrigeration.com

Source: chineserefrigeration.com

62 Fouling Resistance Thermosyphon boilers are designed to achieve a high boiling coefficient. Freechiller annualised Coefficient of Performance COSPs ranges between 10 to 15 depending on design temperature chiller configuration and method of heat rejection. The properly designed thermosyphon receiver will guarantee the preferential flow of liquid refrigerant to the oil cooler before satisfying other system requirements for liquid. When designing a thermosyphon oil cooling system one usually begins with the design oil cooler heat rejection and an assumed refrigerant overfeed rate say 41. Thermosiphon Receiver Liquid Ammonia Reservoir Wanxiang Liquid Storing Container Maker.

Source: esigroupusa.com

Source: esigroupusa.com

You typically design an ammonia thermosiphon chiller to operate around 3 or 4 to 1 circulation ratio. Refrigeration systems professionals at Discovery Designs Refrigeration LLC have the expertise to design and install thermosiphon systems in ammonia or CO2 refrigeration systems. 3 Inlet piping length diameter and details of fittings. When designing a thermosyphon oil cooling system one usually begins with the design oil cooler heat rejection and an assumed refrigerant overfeed rate say 41. How To Build An Ammonia Room Esi Group Usa.

Source: sciencedirect.com

Source: sciencedirect.com

Design Conditions Side A - Evaporating Side B - Liquid Refrigerant R-22 Ref. Vertical high pressure thermosyphon receivers serve as both the system high pressure receiver and as a thermosphon. As a result the fouling resistance may be a major part of the total resistance and is thus a critical factor in the design. 20MPa Water pressure test. Thermosyphons An Overview Sciencedirect Topics.

Source: theengineeringmindset.com

Source: theengineeringmindset.com

3 Inlet piping length diameter and details of fittings. Oliveira et al 2016. Designers of thermosyphon systems strive for a circulation ratio of 31 for ammonia and 21 for R-22 where the circulation ratio means the rate supplied to the heat exchanger divided by the rate evaporated. Our deep knowledge of the principles of refrigeration systems allows us to create custom. Industrial Refrigeration Basics The Engineering Mindset.

Source: haphillips.com

Source: haphillips.com

F 1800 Leaving fluid temp. Pressure a conceptual cycle analysis and preliminary design of a refrigeration system. Refrigeration systems professionals at Discovery Designs Refrigeration LLC have the expertise to design and install thermosiphon systems in ammonia or CO2 refrigeration systems. The thermosiphon design is actually better heat transfer due to the. Thermosyphon Receivers Phillips Refrigeration.